Your Partner in Advanced Powder Toll Processing

Our Core Capabilities: Precision Processing for Every Need

We provide a full spectrum of particle size reduction and material conditioning services, executed on a toll basis to ensure cost-effectiveness and scalability for your operations.

- Particle Size Reduction:

- Jet Milling: Achieving ultra-fine particle sizes, down to less than 1 micron levels, ideal for enhancing bioavailability, dissolution rates, and material performance.

- Micronizing: Fine-tuning particle distribution for improved flowability and consistency.

- Pulverizing: Reducing larger particles to a fine powder.

- Grinding & Milling: Versatile size reduction for a wide range of materials.

- Crushing & Shredding: Initial size reduction for bulkier materials.

- De-lumping: Breaking down agglomerates to restore material uniformity.

- Blending & Mixing:

- Dry Blending: Homogeneously combining multiple dry ingredients for consistent product formulations.

- Mixing: Ensuring thorough dispersion and uniformity of components.

- Compounding: Precisely combining multiple ingredients to create new, specialized formulations.

- Material Separation & Classification:

- Screening & Classifying: Separating materials by particle size to meet particle size distribution specifications.

- Particle Sizing: Accurate measurement and control of particle distribution.

- Additional Specialized Services:

- Re-packing: Efficient and compliant re-packaging of materials into various container types.

- Re-Conditioning: have material that has hardened, in drums, bags, super sacks. We can recondition to free flowing or original condition

- Dry Processing: All our operations are conducted in a dry environment, preventing moisture contamination and preserving material integrity.

State-of-the-Art Facility & Equipment

Our expansive 25,000 sq. ft. facility is meticulously designed for optimal processing and material handling. We leverage a diverse range of cutting-edge equipment to deliver superior results:

-

Particle Reduction Equipment Particle Size Reduction Equipment:

- Jet Mills (Fluidized Bed and Opposed Jet configurations for diverse material properties)

- Hammermills

- Crushers

- Shredders

- Grinders

- Blending & Mixing Equipment:

- Vee Blenders

- Ribbon Blenders

- Stainless Steel Blenders (Ensuring product purity and preventing cross-contamination)

- High-Intensity Mixers (For more challenging blending applications)

- Separation & Analysis Equipment:

- Screeners (Vibratory and Rotary screeners for precise classification)

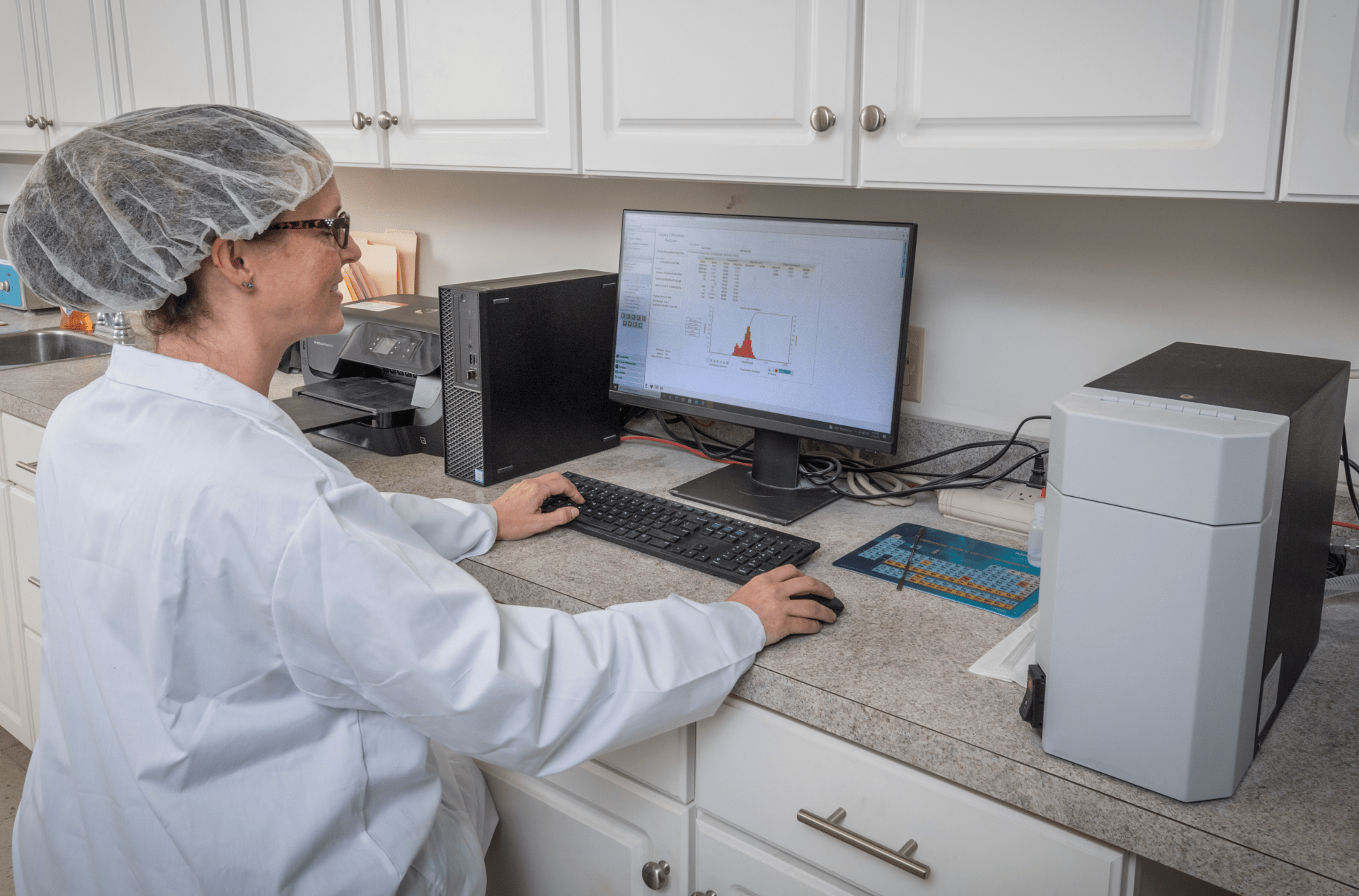

- Particle Analyzing Equipment (e.g., Laser Diffraction Analyzers for accurate particle size distribution data)

Quality Assurance & Certifications: Our Commitment to Excellence

Your peace of mind is our priority. We operate under the strictest quality, manufacturing, and safety protocols, ensuring every batch meets rigorous industry standards.

-

Laboratory Testing Regulatory Compliance:

- FDA Registered Facility

- OSHA Compliant

- Quality Management Systems:

- GFSI (Global Food Safety Initiative) Compliant

- SQF (Safe Quality Food) Certified

- ISO 9001:2015 Certified

- HACCP (Hazard Analysis and Critical Control Points) Compliant (Essential for food safety)

- Dietary & Religious Certifications:

- Halal Certified

- Kosher Certified

Versatile Materials & Fineness Range

We specialize in processing a broad spectrum of dry materials and powders, delivering precise particle fineness to suit your specific application:

- Materials Processed (Examples):

- Food Ingredients (e.g., flours, starches, spices, sugar substitutes)

- Organic Ingredients

- Specialty Chemicals (e.g., pigments, resins, catalysts)

- Pet Food Nutritionals

- Sodium Benzoate

- Creatine Powders

- Nutraceutical Products (e.g., vitamins, herbal extracts, dietary supplements)

- Proteins (e.g., whey protein, plant-based proteins)

- Amino Acids

- Fillers (e.g., excipients for pharmaceuticals, industrial fillers)

- Coatings (e.g., powder coatings, industrial finishes)

- Minerals (e.g., industrial minerals, specialty mineral powders)

- Cosmetics (e.g., mineral makeup, active ingredients)

- Powder Fineness Range: From 500 microns down to less than 1 micron, with capabilities for achieving even finer cuts depending on material characteristics and equipment.

Comprehensive Packaging & Logistics Solutions

Beyond processing, we offer a diverse array of packaging options to streamline your supply chain and ensure product integrity from our facility to yours.

- Packaging Options Include:

- Automatic Bagging

- Super Sacks (FIBCs)

- Drum Filling

- Bags in Boxes

- Custom Packaging Solutions (Upon request, for specialized needs)

- Private Label Packaging (For seamless brand integration)

Expert Laboratory & R&D Services

Our well-equipped laboratory is a cornerstone of our service, providing critical insights and collaborative opportunities.

-

Laboratory & R&D Services Laboratory Services:

- Precise Particle Size Analysis: Utilizing advanced equipment for accurate particle distribution measurements and reporting.

- Certificate of Analysis (COA’s): Provided with every batch to confirm material specifications.

- Research & Development (R&D): Collaborative services to optimize existing processes, develop new products, and troubleshoot challenges.

- Lab Test Mill: Dedicated equipment for small-batch testing, pilot runs, and client collaborations on special projects.

- Preliminary Engineering & Process Design: Offering expertise in developing efficient and scalable processing solutions.

Unmatched Service & Lead Times

At CPR, quality and superior service are our paramount priorities. We are dedicated to providing the shortest possible lead times in the industry without compromising on excellence.

- Lead Times: Quoted on a job-by-job basis, tailored to your specific project requirements.

- Flexible Services:

- Rush Services Available: For urgent project needs.

- Just-In-Time (JIT) Services: Available upon request to support lean inventory management.

Industries We Proudly Serve

Our expertise extends across a diverse range of industries, delivering tailored solutions for critical applications:

- Biopharmaceutical

- Biotechnology

- Chemical

- Cosmetics

- Dental

- Food & Beverage

- Industrial

- Laundry

- Medical

- Nutraceuticals

- Personal Care

- Pharmaceuticals

- Agricultural (e.g., fertilizers, crop protection products)

- Coatings & Adhesives

To find out more about how Custom Particle Reduction’s world-class tolling services can benefit your business, contact us directly today for a personalized consultation.